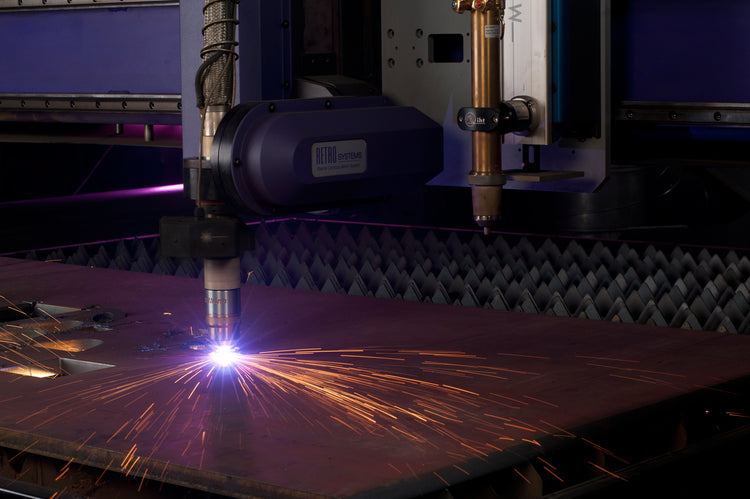

Collection: Plasma Cutting

Compressed air often contains moisture, which can negatively impact the performance of the plasma-cutting process. Moisture in the air can lead to poor cut quality, reduced consumable life, and potential damage to the plasma torch. In addition to humidity, compressed air can carry impurities such as oil, dust, and other contaminants. These impurities can clog or damage the internal components of the plasma cutter, affecting its efficiency and requiring more frequent maintenance. We offer various desiccant air dryers with lower dew points than the Devilbiss DAD 500 or Devilbiss CT30.

-

ATD 1/4 -Air Tool Dryer

Regular price $265.00 USDRegular priceUnit price / per -

ATD 1/2 -Air Tool Dryer

Regular price $265.00 USDRegular priceUnit price / per -

ATD 1/4 XL -Air Tool Dryer

Regular price $495.00 USDRegular priceUnit price / per -

D1 - Desiccant Air Dryer

Regular price $993.75 USDRegular priceUnit price / per -

D2 - Desiccant Air Dryer

Regular price $1,656.25 USDRegular priceUnit price / per